FAQs About Titanium Coated Hair Cutting Tools

Titanium-coated hair tools combine Japanese steel with a thin titanium layer, offering durability, sharpness, and smoother cuts. These tools are popular among hairstylists due to their long-lasting performance, lightweight design, and hypoallergenic properties, making them suitable for all hair types and sensitive skin.

Key Features:

- Durability: Lasts 3–4 times longer than non-coated tools.

- Sharpness: Retains edge longer for precise cuts.

- Hypoallergenic: Safe for sensitive skin or metal allergies.

- Lightweight: Reduces hand fatigue during extended use.

- Corrosion Resistance: Ideal for humid environments.

Maintenance Tips:

- Clean with mild soap and dry thoroughly after use.

- Store in protective cases to prevent damage.

- Use professional sharpening services every 6–12 months.

Why Choose Saki Shears:

- Crafted using premium Japanese steel (440C, VG-10, Damascus).

- Lifetime warranty with free shipping and returns.

- Ergonomic design for comfort and performance.

For professionals, titanium-coated tools ensure reliable, precise results while reducing wear and maintenance efforts.

Benefits of Titanium Coated Hair Cutting Tools

Durability and Resistance

Titanium-coated hair cutting tools are built to last. The titanium coating acts as a protective barrier, significantly extending the lifespan of the tools. With a hardness value exceeding 2,500 Vickers hardness (HV), titanium nitride coatings offer exceptional resistance to wear and heat. This durability means these tools can last 3 to 4 times longer than their non-coated counterparts.

Additionally, titanium’s natural corrosion resistance, thanks to its self-protecting oxide layer, helps prevent rusting - even in humid salon environments. This strength not only keeps the tools in good shape but also ensures the blades maintain their form, supporting long-term sharpness and precision.

Sharpness and Cutting Precision

One of the standout features of titanium-coated tools is their ability to maintain a sharp edge over time. These tools stay sharper much longer than traditional steel alternatives, providing consistent performance throughout their lifespan. This means fewer sharpening sessions and more reliable results for every cut.

Titanium’s molecular strength also plays a role in precision. Because titanium is tougher than steel, titanium-coated scissors retain their sharpness longer, offering a higher level of hardness in the blades. This ensures every cut is precise and smooth, making them an essential tool for professionals.

Hypoallergenic Properties

Beyond durability and precision, titanium-coated tools bring an added layer of safety, especially for clients with sensitive skin or metal allergies. Titanium is far less likely to cause allergic reactions compared to other metals.

"Titanium is less likely to cause allergic reactions compared to some other metals. This makes titanium-coated scissors a safer choice for barbers and clients with metal sensitivities."

Gold titanium blades, in particular, are celebrated for their hypoallergenic qualities, making them ideal for sensitive skin. As StyleCraft highlights:

"Offers hypoallergenic properties that are ideal for sensitive skin, easy to sanitize, and perfect all-around hair cutting."

- StyleCraft

This combination of durability, sharpness, and skin-friendly properties makes titanium-coated tools a top choice for professionals seeking high-performance and client comfort.

FX4072 Titanium-Coated Hair Scissors: Precision Meets Elegance

Care and Maintenance of Titanium Coated Tools

Taking good care of your titanium-coated tools ensures they maintain their sharpness and last for years.

Cleaning and Maintenance Tips

After every use, wipe your tools with a lint-free cloth to remove hair, product buildup, and oils. For a deeper clean, use mild soap with warm water, and when disinfecting, opt for alcohol-based sanitizers specifically designed for professional hair tools.

Avoid using harsh chemicals or abrasive cleaners - they can damage the titanium coating. Once cleaned, make sure your tools are completely dry before storing them. While titanium coatings are known for resisting corrosion, lingering moisture can still cause problems, especially around the pivot area where the coating may be thinner.

Once your tools are clean and dry, proper storage is essential to keep them in top shape.

Proper Storage Practices

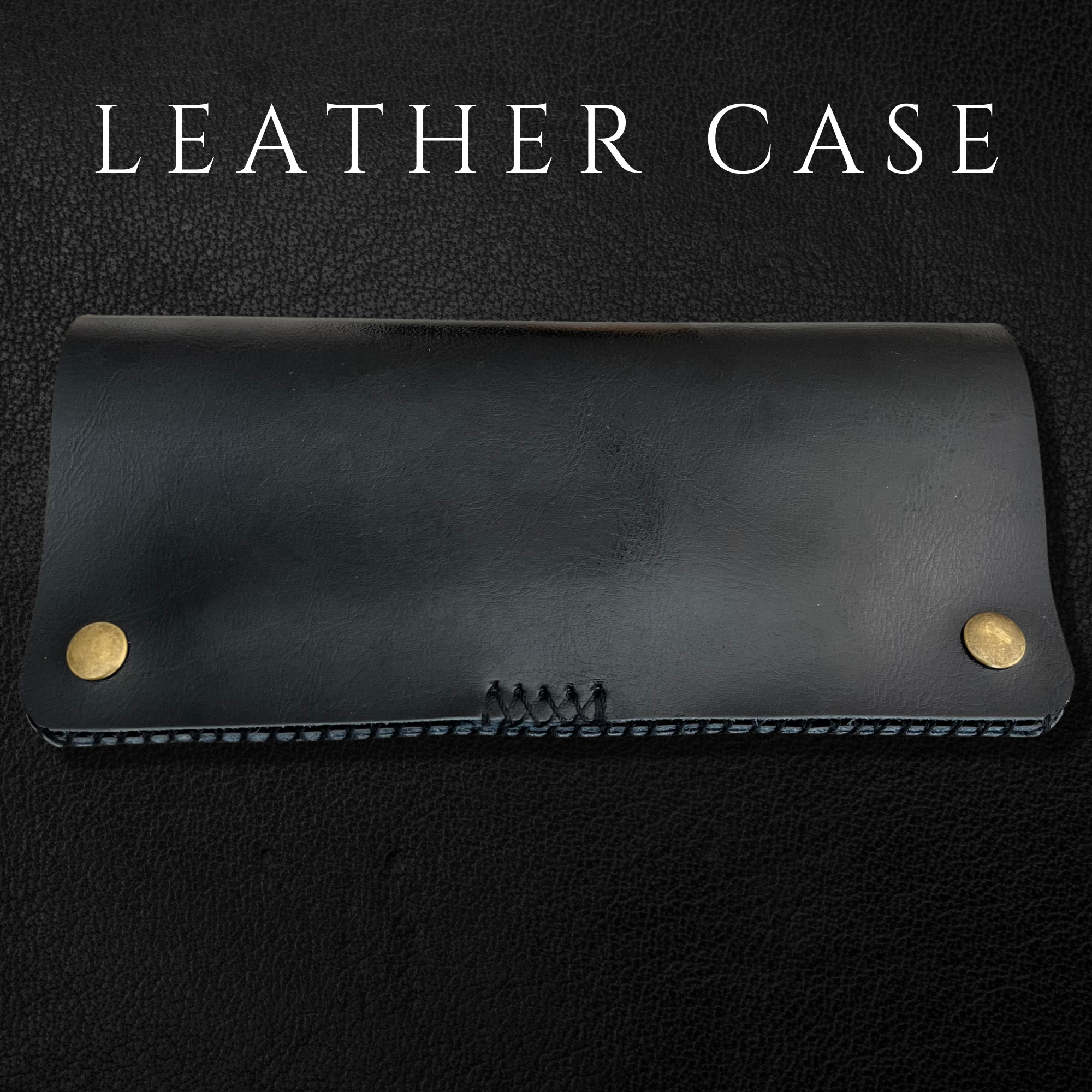

Store your tools in a dedicated shear case, barber tool roll, or protective pouch. This prevents damage to the coating and keeps the blades sharp by avoiding contact with other surfaces or tools.

Ensure your storage area is dry and at room temperature. Extreme temperature fluctuations can cause the metal beneath the coating to expand or contract, which could weaken the bond between the titanium layer and the steel.

Avoid tossing your tools into a drawer or bag with other items. Even though the titanium coating is durable, it can still chip or scratch if it comes into contact with harder materials. Using individual blade guards or designated slots in a tool case is the best way to prevent this.

Proper storage reduces the frequency of sharpening and keeps your tools in great condition.

Sharpening and Handling

To maintain the sharpness and integrity of your titanium-coated tools, have them professionally sharpened every 6–12 months. The exact timeline depends on how often and what type of hair you cut. For instance, if you’re working with 6–8 wet-hair clients daily, inspect your tools every six months. If you primarily cut dry hair, aim to check them every four months.

Always rely on professional sharpening services. While it might seem like a cost-saving idea to sharpen tools yourself, it can backfire:

"Many new stylists think they can save money by using DIY methods to sharpen their expensive shears. I learned the hard way early in my career when I ruined a pair of Damascus steel shears. Now, I always emphasize to my students the importance of professional sharpening, especially for premium shears." - Anna, Stylist and Trainer

Professionals understand the specific needs of titanium-coated tools and use methods that preserve both the coating and the underlying steel. They’ll also remove only the minimum material necessary to restore the edge, ensuring your tools last longer.

Handle your tools with care and use them exclusively for cutting hair. While the titanium coating adds durability, impacts can still cause chips or cracks. Be gentle when passing tools to colleagues or setting them down to prevent unnecessary damage.

Investing time in proper care pays off. Well-maintained titanium-coated tools can outlast poorly cared-for ones by years, making your initial investment worthwhile in the long run.

sbb-itb-3cc0078

Professional Usage Tips for Titanium Coated Tools

Get the most out of your titanium-coated tools by tailoring your techniques to suit different hair types and cutting scenarios.

Performance Across Hair Types

Titanium-coated tools shine when working with thick, coarse, or curly hair. The coating helps blades glide smoothly through dense hair, reducing pulling and snagging. This makes them an excellent choice for clients with textured or chemically treated hair, where precision and comfort are key.

For fine or thin hair, a lighter touch is essential. The sharpness of titanium-coated blades means you can achieve clean cuts without applying much pressure. Start gently, adjusting your technique as needed based on how the hair responds. Plus, the reduced friction minimizes static buildup, a common issue with fine hair that tends to fly away.

When cutting wet hair, these tools maintain their efficiency far better than uncoated options. The titanium coating prevents hair and moisture from sticking to the blades, so you won’t need to stop frequently for cleaning. This keeps your workflow smooth, even during busy salon days.

With curly and textured hair, the anti-friction properties of the coating are a game-changer. The smooth blade surface prevents catching on individual curls, allowing for precise sectioning and cutting. This is especially helpful when creating layers or maintaining natural curl patterns during texture work.

Proper Cutting Techniques

Once you’ve tailored your approach to the hair type, refine your cutting technique to make the most of your tools. Take advantage of the ergonomic, lightweight design to reduce hand fatigue. Position your fingers comfortably in the finger holes and use your thumb to control the motion, avoiding a tight grip with your entire hand.

Adjustable tension systems are particularly effective with titanium-coated tools. Begin with medium tension and tweak it based on the hair you’re cutting. For thicker hair, slightly tighter tension ensures clean cuts, while looser tension is ideal for fine hair to avoid over-cutting or damage.

The point cutting technique works beautifully with these tools. Hold the shears at a 45-degree angle and make small, controlled cuts into the ends of the hair. This technique not only enhances precision but also helps maintain the sharpness of the blades.

For slide cutting, the titanium coating provides excellent control. Start at the mid-length of the hair section and slide the partially open shears down toward the ends. The smooth surface minimizes drag, giving you greater control over how much hair is removed.

When texturizing, the reduced friction of the coating ensures cleaner cuts through the hair shaft, resulting in a more natural texture. Use decisive, controlled cuts rather than hesitant ones to fully capitalize on the tool’s capabilities.

Longevity Through Proper Usage

Proper care and usage are key to extending the life of your titanium-coated tools. Reserve these shears exclusively for cutting hair. While titanium coatings are durable, using them to cut non-hair materials like tape or packaging can chip the coating and dull the blades. Keep a separate pair of utility scissors at your station for such tasks.

Handle your tools carefully to avoid impacts that could compromise the coating. When setting them down, place them gently on a towel or in a designated holder to prevent accidental damage.

Stay within the tools’ design limits. Forcing your shears through hair that’s too thick for their blade length or overloading them can strain both the coating and the underlying steel. If you’re handling high-volume cutting, consider alternating between pairs. Rotating two or three pairs of titanium-coated tools allows each set to “rest,” reducing wear and prolonging their lifespan.

Pay close attention to your cutting angles. Keeping the blades aligned during cuts ensures even wear on the coating. Twisted or angled cuts can create uneven pressure, leading to premature wear in specific areas.

Finally, combine these practices with regular cleaning and maintenance. Monitor your tools for signs of wear, such as increased drag or difficulty cutting. If you notice these issues, it’s time for professional sharpening or servicing. Continuing to use dull tools can damage both the coating and your cutting results, so staying proactive is essential for long-term performance.

Why Choose Saki Shears Titanium Coated Tools

Saki Shears takes everything a professional hairstylist or barber needs and combines it with precision craftsmanship, premium materials, and dependable support. Choosing tools with titanium coating isn't just about durability - it's about ensuring every cut meets the highest standards.

Craftsmanship and Material Quality

Saki Shears uses top-tier Japanese steel to craft its titanium-coated tools, offering three distinct grades: 440C, VG-10, and Damascus. Each grade caters to different professional requirements:

- 440C Steel: Known for its durability and sharp edge retention, this option is reliable and budget-friendly.

- VG-10 Steel: Offers superior edge retention and resistance to corrosion, making it ideal for demanding environments.

- Damascus Steel: Renowned for its unmatched strength and striking wavy design, this is the pinnacle of high-performance shears.

Every pair of Saki Shears is meticulously hand-crafted, ensuring precision that mass-produced tools simply can't achieve. The titanium coating is applied with advanced techniques, creating a tough, uniform surface that bonds permanently with the steel. Ergonomic details, like carefully positioned finger holes, are designed to reduce hand fatigue, even during long workdays.

Lifetime Warranty and Customer Support

Saki Shears goes the extra mile to stand behind its titanium-coated tools with a lifetime warranty that covers material and workmanship defects. Their policy is clear and professional:

"All Saki Shears are covered under our lifetime warranty unless specified otherwise. Saki Shears are warranted to be completely free of material and workmanship defects. We will repair or replace any shears that we find are defective or malfunctions."

If your shears ever experience issues like coating wear, blade misalignment, or other manufacturing defects, Saki Shears will repair or replace them at no charge. They also offer an accidental damage protection plan, with replacement fees based on the model: $50 for 440C, $100 for VG-10, $200 for most Damascus models, and $350 for the premium Kamakura Damascus model.

And that's not all. Saki Shears offers free shipping and free returns on all their products, along with a 30-day return policy and dedicated customer support (cs@sakishears.com). This ensures you can try their tools risk-free.

Designed for Professionals

Saki Shears understands the demands of hairstylists and barbers. Their tools are engineered to make your job easier, with adjustable tension systems that let you fine-tune blade pressure for different hair types without disrupting your workflow. Thoughtful weight distribution minimizes wrist strain, so you can work comfortably for hours.

The blade geometry is carefully designed to maximize the benefits of the titanium coating, ensuring sharp, precise cuts every time. With a range of blade lengths, you can choose the perfect size for your techniques and hand size.

To round things out, Saki Shears includes professional-grade accessories like storage cases, cleaning tools, and maintenance guides tailored for titanium-coated models. You can also opt for shear sets that include cutting and thinning shears with matching specifications, ensuring top-notch performance across your toolkit.

When you invest in Saki Shears titanium-coated tools, you're choosing equipment built for professionals, backed by a company that truly understands the craft. From premium materials to unmatched support, Saki Shears is committed to helping you excel in your work.

Conclusion

Titanium-coated hair-cutting tools stand out for their durability, precision, and reliability, making them a valuable choice for professionals. They not only streamline daily tasks but also provide a comfortable experience for both the stylist and the client.

Designed to be both sturdy and lightweight, these tools maintain their sharpness for longer, reducing the need for frequent sharpening and minimizing maintenance efforts. With proper care - like regular cleaning, safe storage, and professional sharpening - they deliver consistent, precise performance over time.

When every cut counts, investing in high-quality tools is essential. Saki Shears offers premium Japanese steel combined with advanced titanium coating, ensuring exceptional craftsmanship. With a lifetime warranty, free shipping, and dedicated customer support, Saki Shears provides tools that elevate the quality of your work and enhance your daily comfort. For professionals who take their craft seriously, titanium-coated tools are the reliable partner you can count on.

FAQs

What are the benefits of titanium-coated hair cutting tools compared to non-coated ones?

Titanium-coated hair cutting tools bring some standout benefits to the table. Thanks to the titanium coating, the blades are much harder, which helps them stay sharp for a longer time and handle more cuts throughout their use. This added toughness means you won’t need to sharpen or replace them as often.

Another big plus? These blades resist rust, corrosion, and general wear, so they stay in great shape even with frequent use. They also handle heat exceptionally well, making them a solid choice for professional hairstylists who depend on durable, high-performing tools day in and day out.

How can I properly care for and maintain titanium-coated hair cutting tools to keep them performing their best?

To keep your titanium-coated hair cutting tools in excellent shape, start by giving the blades a daily wipe-down with a lint-free cloth. This clears away hair, moisture, and any lingering residue. For proper sanitation and to avoid buildup, use an alcohol-based disinfectant.

Each week, apply 2-3 drops of shear oil at the pivot point. This keeps the blades moving smoothly and helps protect them from rust. For a deeper clean, set aside time once a month to thoroughly disinfect the tools, clear out any debris, and reapply oil.

When you're not using your tools, store them in a protective case to prevent damage. Also, make it a habit to check the tension adjustment regularly to ensure the blades are working efficiently. By following these steps, you’ll extend the life and maintain the performance of your titanium-coated tools.

Why are titanium-coated hair cutting tools a good choice for clients with sensitive skin or metal allergies?

Titanium-coated hair cutting tools are a great choice for clients who have sensitive skin or allergies to certain metals. Why? Because titanium is hypoallergenic, meaning it’s far less likely to trigger skin irritation or allergic reactions. For those with sensitivities, this can make all the difference in ensuring a comfortable experience.

But there’s more to titanium than just being gentle on the skin. It’s also incredibly durable and resistant to corrosion. This means that these tools not only maintain their sharpness and smooth finish over time but also minimize the chance of irritation caused by wear and tear. With its perfect blend of strength and skin-friendliness, titanium-coated tools are a dependable option for hairstylists who want the best for their clients.