How Corrosion Affects Hair Cutting Scissors

Corrosion can ruin your hair cutting scissors by dulling the blades, increasing friction, and causing hair to snag during cuts. It happens when moisture, oxygen, and chemicals react with the metal, forming rust. This is especially common in humid salons or when scissors are exposed to water, hair products, and improper storage.

To prevent corrosion:

- Clean and dry scissors daily to remove moisture and residue.

- Oil blades weekly to create a protective barrier.

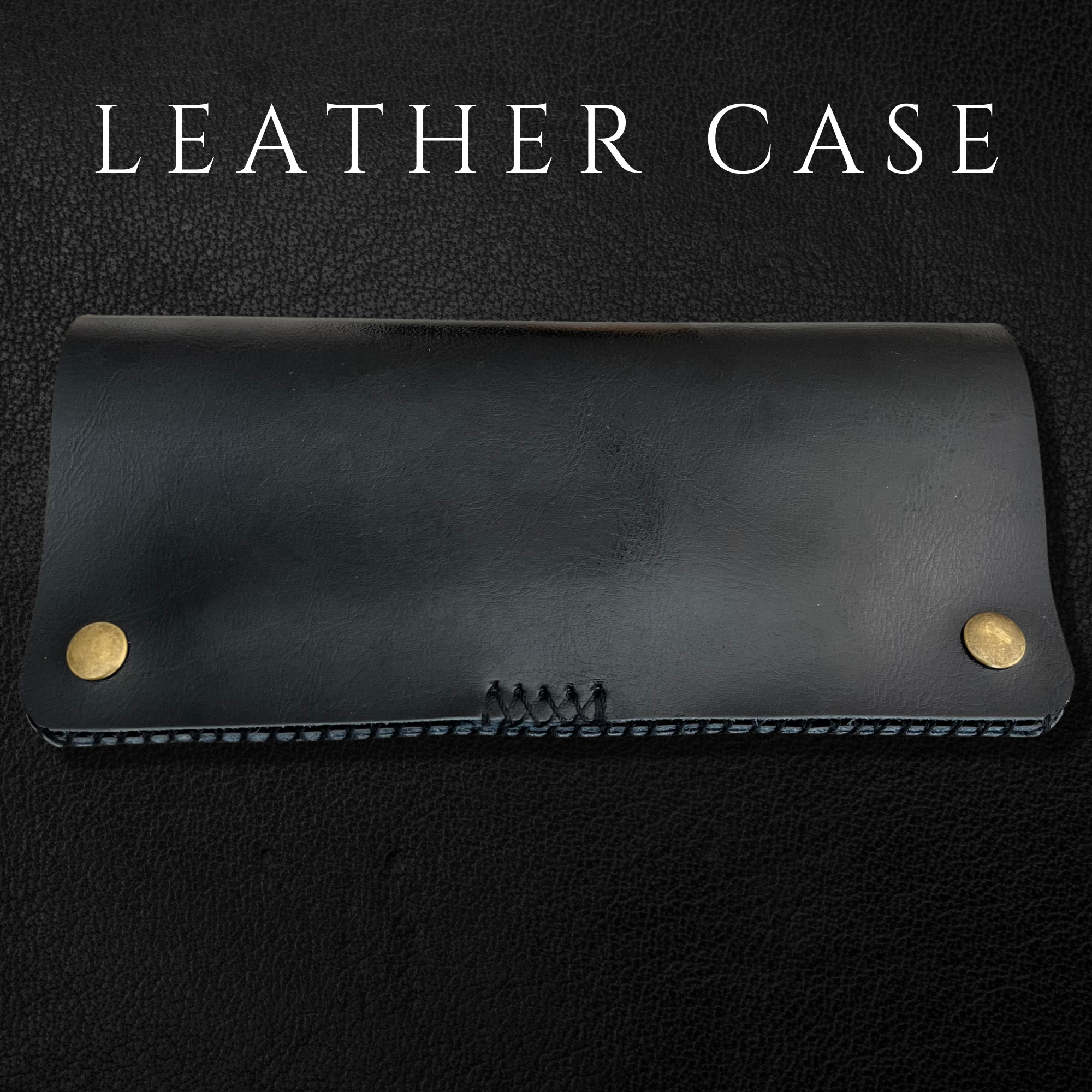

- Store in a dry case with silica gel packets to absorb humidity.

- Use high-quality steel scissors, like those made from 440C or VG-10 stainless steel, for better rust resistance.

If rust appears, buff it with fine steel wool or soak in vinegar for minor spots. Severe rust may require professional sharpening. Proper care extends the life of your tools and ensures precise cutting performance.

SCISSOR MAINTENANCE - How to clean, oil and tension barber & hairdressing shears to keep them sharp!

What Causes Corrosion in Hair Cutting Scissors

After understanding the damage corrosion can cause, it’s essential to pinpoint the factors that lead to it. In professional salon settings, scissors are constantly exposed to conditions that can wear down even the toughest steel. Here’s a closer look at the key contributors to scissor corrosion.

Moisture and Water Damage

Moisture is the number one enemy of scissors. Whether it’s from cutting wet hair, cleaning the tools, or working in humid, steamy salons, water exposure significantly speeds up rust formation. Even a small amount of leftover moisture after cleaning or cutting wet hair can trigger rust, especially in humid conditions.

Temperature swings make matters worse. Moving between air-conditioned salons and humid outdoor environments creates condensation on the scissors. This constant cycle of expansion and contraction stresses the metal, paving the way for corrosion.

Chemical Exposure in Salons

Salon chemicals, like ammonia-based dyes, bleaches, and perming solutions, can be highly corrosive. These substances react with the steel, eroding its protective surface and accelerating damage. When you cut chemically treated hair, traces of these products often stick to the scissors. Even with thorough cleaning, some residue may remain, especially if the chemical reaction with the metal has already begun. Combined with moisture, this chemical exposure creates a perfect storm for corrosion.

Poor Storage and Environmental Conditions

How scissors are stored matters just as much as how they’re used. Storing tools in damp environments, near heat sources, or in places with fluctuating temperatures can speed up rust and wear. Many stylists unknowingly contribute to corrosion by not storing their scissors properly.

Environmental factors, such as high humidity, also play a role. During summer months or in naturally humid regions, scissors are exposed to ongoing moisture, which is difficult to avoid entirely. However, proper storage practices can help counter these challenges.

| Environmental Factor | Impact on Scissors |

|---|---|

| High Humidity | Speeds up oxidation and rust formation |

| Temperature Fluctuations | Leads to condensation and metal stress |

| Damp Storage | Encourages rust to develop |

| Direct Sunlight/Heat | Weakens durability through temperature shifts |

Corrosion occurs when moisture, chemicals, and improper storage combine to degrade your scissors over time. Knowing these factors allows you to take proactive steps to protect your tools and maintain their performance. By addressing these issues, you can extend the lifespan of your scissors and keep them in top condition.

How Corrosion Hurts Scissor Performance

Corrosion doesn’t just tarnish the look of your scissors; it directly impacts how well they perform. Over time, it can lead to dull blades and increased friction, making smooth, precise cuts much harder to achieve. Let’s break down exactly how this happens.

Dull Blades and Poor Cutting

When corrosion sets in, it damages the cutting edge of the blades, leaving pits and rough spots. This dulling effect ruins the sharp, clean surface that scissors need for precise cuts. Instead of slicing through hair, corroded blades tend to crush or tear hair fibers, which can result in frayed ends, split hairs, and uneven cuts. For professionals, this loss of precision can make it difficult to deliver high-quality results.

More Friction and Hair Snagging

Corrosion also creates surface irregularities that increase friction during cutting. The roughened blades drag against each other and the hair, causing snagging or even folding of hair strands instead of cutting them cleanly. This added resistance means you have to apply more force, which can lead to hand fatigue and even repetitive strain injuries over time. If left unchecked, this strain can warp the blades, eventually making the scissors unusable.

| Performance Impact | Immediate Effect | Long-term Consequence |

|---|---|---|

| Blade Sharpness | Crushing and tearing of hair fibers | More frequent maintenance needed |

| Cutting Precision | Uneven, inaccurate cuts | Poorer styling results |

| Physical Strain | Hand fatigue and extra force required | Higher risk of repetitive strain injuries |

| Tool Lifespan | Warping of blades | Tool ineffectiveness |

sbb-itb-3cc0078

How to Prevent and Fix Corrosion

Keeping your scissors free of corrosion is entirely possible with a bit of regular care. With the right routine, you can prevent rust and even tackle it before it causes permanent damage. Here’s how to keep your scissors in excellent shape.

Daily Cleaning and Drying

After every use, clean your scissors with a soft cloth or brush, especially around the pivot area. This removes hair, product residue, and moisture that can lead to rust. Once cleaned, make sure to dry every surface thoroughly - moisture, even in tiny amounts, can kickstart oxidation.

Pay close attention to areas like the screw and inner blade edges, as these are often overlooked. Avoid leaving wet scissors on countertops or wrapped in damp towels, as this creates the perfect environment for rust to form. A few minutes of care after each use can go a long way in preserving your scissors.

Regular Maintenance and Oiling

Set aside time weekly to apply a few drops of scissor oil to the blades and pivot. This creates a protective barrier against moisture and helps keep the cutting action smooth. Open and close the scissors several times to distribute the oil evenly. For the best results, use mineral oil or oil specifically designed for scissors.

This simple step not only prevents rust but also ensures your scissors maintain their precision and functionality over time.

Correct Storage Methods

Storage plays a big role in preventing corrosion. Always keep your scissors in a dry, ventilated case rather than leaving them exposed to humid salon conditions. A case with individual slots is ideal, as it prevents the blades from rubbing against other metal objects, which can lead to scratches or accelerate corrosion.

Avoid storing scissors near sinks or in poorly ventilated drawers where humidity tends to linger. If you’re in a particularly humid climate, adding silica gel packets to your storage case can help absorb excess moisture and keep your scissors rust-free.

Removing Existing Rust

If you notice minor rust spots, you can buff them out using fine steel wool. Use small, circular motions with gentle pressure to avoid damaging the metal. For tougher rust, disassemble the scissors (if possible) and soak the affected parts in white vinegar for 1–2 days. The vinegar’s acidity breaks down the rust without being overly harsh on the metal.

Once the rust is removed, wash the scissors, dry them immediately, and apply a thin coat of oil to protect the exposed metal.

For severe rust - especially if it covers large areas, creates deep pits, or affects the cutting edge - it’s best to consult professional sharpening services. Attempting to fix extensive corrosion yourself could compromise the blade’s precision. Tackling rust early not only saves your scissors but also ensures they stay sharp and reliable for years to come.

How Material Quality Affects Corrosion Resistance

The type of steel used in your scissors is a game-changer when it comes to resisting rust and corrosion. Basic carbon steels are far more susceptible to moisture and chemical damage, while higher-grade steels provide better corrosion resistance and maintain their sharpness longer. This highlights the importance of choosing quality materials as the first step in preventing rust, building on the earlier discussion about proper maintenance.

Rust-Resistant Steel Types

Premium Japanese steels like 440C, VG-10, and Damascus are well-known for their ability to resist corrosion. These steels achieve their durability through high chromium content, specialized heat treatments, and, in some cases, layered construction.

- 440C Stainless Steel: This steel stands out for its high chromium levels, which form a protective oxide layer that prevents rust. It's also designed to retain its sharp edge, even when exposed to the moisture and chemicals found in salon environments.

- VG-10 Steel: Engineered to balance exceptional edge retention with strong resistance to corrosive conditions, VG-10 is a favorite among professionals who need reliable performance.

- Damascus Steel: Known for its striking layered patterns, Damascus steel combines hardness for precise cutting with excellent rust resistance. The traditional folding process not only enhances its visual appeal but also strengthens its ability to resist corrosion over time.

These steels are ideal for handling the constant exposure to salon chemicals, frequent washing, and humid conditions that can quickly wear down lower-quality materials.

Saki Shears: Quality Materials

Saki Shears incorporates these premium steels into their products, ensuring they can endure the daily demands of salon work. Their tools are designed for both rust resistance and precise cutting, thanks to meticulous craftsmanship.

Each pair of Saki Shears undergoes a handcrafted manufacturing process that creates a uniform steel structure, minimizing microscopic gaps where moisture could sneak in. Their specialized heat treatments enhance both the hardness and the corrosion resistance of the steel, ensuring consistent performance even in tough environments.

Many Saki Shears models also feature titanium coatings, which add an extra layer of protection against chemicals while reducing friction for smoother cuts. This coating makes cleaning easier and prevents product buildup, which could otherwise trap moisture and lead to rust.

Lifetime Warranty Protection

Saki Shears backs their products with a lifetime warranty, reflecting their confidence in the durability and corrosion resistance of their tools. This warranty covers manufacturing defects and premature issues like rust or corrosion, provided the scissors are properly maintained.

The warranty also includes free shipping for repairs or replacements, making it hassle-free to address any problems. This level of support not only protects your investment but also complements regular cleaning and care practices.

Protecting Your Hair Cutting Scissors Investment

Your professional scissors are a cornerstone of your career, and taking steps to protect them from corrosion is key to maintaining their performance and extending their lifespan. While no scissors are completely rust-proof, proper care can make all the difference in preserving your tools.

The secret to keeping your scissors in top shape is building consistent daily habits. After every use, wipe them down with a microfiber cloth to remove any residue that could lead to corrosion. Never store your shears while they’re wet - moisture is the main culprit behind rust, as it triggers oxidation when iron in the steel reacts with oxygen. Regular cleaning combined with routine oiling provides a strong defense against corrosion.

Make a habit of oiling your scissors three to four times a week. Open and close them 10–20 times after applying the oil to ensure it spreads evenly across the blades. This routine helps prevent moisture from settling on the steel, keeping your scissors in peak condition.

When it comes to storage, always keep your shears in a dry, protective case with silica gel packets to absorb any excess moisture. Avoid humid environments and ensure the blades don’t touch each other, as contact can cause damage over time.

For added durability, choose scissors made from high-quality steel, like those found in Saki Shears. Premium materials not only enhance rust resistance but also reduce the amount of maintenance required, giving your tools a longer life.

FAQs

How can I protect my hair cutting scissors from rust in humid conditions?

To keep your hair-cutting scissors in top shape, especially in humid environments, proper care is key. Start by wiping the blades with a clean, dry cloth after every use to remove moisture and hair residue. This simple habit prevents buildup and keeps the blades clean.

Regularly apply a light layer of shear oil to the blades and pivot area. This not only protects against rust but also ensures smooth operation. When you're not using the scissors, store them in a protective case. For added protection, include a desiccant pack or silica gel inside the case to absorb any excess moisture.

By following these straightforward steps, you can keep your scissors rust-free and performing well for years to come.

How does the type of steel used in hair cutting scissors affect their resistance to rust and performance?

The type of steel in hair cutting scissors is a game-changer when it comes to rust resistance and performance. High-end options like Japanese VG-10, ATS-314, and 440C stainless steel are known for their outstanding durability, resistance to corrosion, and ability to keep a razor-sharp edge over time. These qualities are critical for professional hairstyling tools that see constant use.

Scissors crafted from such premium steel not only stay rust-free but also deliver smoother, more precise cuts and maintain their sharpness longer. Choosing high-quality materials protects your tools from moisture and salon chemicals, helping them last longer and perform consistently.

What should I do if I see rust forming on my hair cutting scissors?

If you spot rust forming on your hair cutting scissors, it's important to address it right away to prevent further damage. Start by soaking the scissors in white vinegar for a few hours - this helps loosen the rust. After soaking, gently scrub the rusty spots using a non-scratch pad or fine steel wool. Once the rust is gone, wipe the scissors clean, dry them thoroughly, and apply a light coat of oil to protect the metal and guard against future rust.

To keep rust at bay, always store your scissors in a dry place and clean them regularly. With proper care, your scissors will stay sharp and ready for use for years to come.